The financial implications of the IIoT and, on a wider scale, Industry 4.0 are constantly changing. This is, in large part, because the underlying technology enabling the IIoT is itself evolving.

The financial implications of the IIoT and, on a wider scale, Industry 4.0 are constantly changing. This is, in large part, because the underlying technology enabling the IIoT is itself evolving.

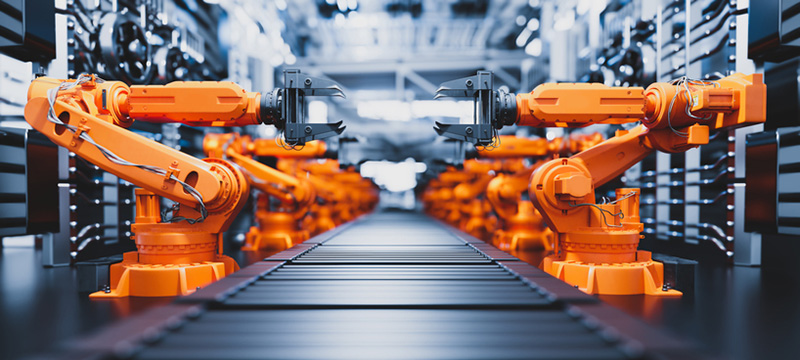

Change isn’t welcome in most areas of manufacturing. Any change represents risk, and even when that change brings with it almost guaranteed gains the risks remain. Many OEMs are now assessing the risk and reward of letting the internet onto their shopfloor.

Most of the time we don’t go looking for change, it is forced upon us. What really matters is how we manage that change. This is where many of those manufacturers now find themselves with their assessment of the IIoT.

It may feel like a herculean task. The scale can be overwhelming but as with most tasks it needs to be broken down into manageable efforts. What is it they say about Rome? The perceived problem is that, unlike Rome, manufacturers are not starting with a clean piece of paper. Neither do they have the luxury of letting style overtake substance.

But like any large structure, getting the foundations right is probably the most important step. It may involve some remodeling, but if those foundations are solid the rest should follow. This is happening in the IIoT. New technologies are being developed to provide the scalable, solid foundation needed to bring existing manufacturing plants into the IIoT.

Services bring the IIoT together

The practice of delivering ‘X as a Service’ is already strong, and not only in traditional service industries. One often cited example is the jet-engine as a service offered by Rolls-Royce. Turning ‘things’ into services makes them much more manageable because it creates uniformity and removes superfluous complexity at the interface.

The same concept is now being used in the deeply embedded domain. Turning functions into services makes those functions more accessible across domains. This is the subject of an Avnet article , which takes a look at the technologies being developed to support the move to services in the industrial IoT.

Making the IIoT simpler

The internet provides the critical infrastructure for connectivity. The IoT takes advantage of this infrastructure to allow any device, anywhere, to become part of that wider network. The Industrial IoT represents a slice of this wider network, one that puts safety and security above almost anything else.

The internet provides the critical infrastructure for connectivity. The IoT takes advantage of this infrastructure to allow any device, anywhere, to become part of that wider network. The Industrial IoT represents a slice of this wider network, one that puts safety and security above almost anything else.

As industrial connectivity predates the IoT there are many legacy networks that now need to be integrated. Doing that safely is part of the challenge, but so too is removing the complexity that already exists within these different networks.

Ethernet is the single most common protocol used in the information technology domain. Its use is now permeating other verticals, including the industrial sector. But Ethernet alone cannot meet all the requirements imposed by the industrial world.

To address this, the IEEE has developed standards for single pair Ethernet (SPE). This relatively simple development has huge implications across the IIoT. In the article , Avnet talks with George Zimmerman, the chair of the IEEE Ethernet task force and independent consultant on high-speed communications technology to find out why.

Taking control at the network edge

An important aspect to remember in this transition is that industrial control is often a real-time application. In the example above, SPE may only be viable in an industrial setting if time-sensitive networking (TSN) technology is also applied.

An important aspect to remember in this transition is that industrial control is often a real-time application. In the example above, SPE may only be viable in an industrial setting if time-sensitive networking (TSN) technology is also applied.

This real-time imperative propagates throughout the network, all the way to edge. This is where the control resides, typically in the form of a programmable logic controller, or PLC. These highly optimized embedded devices have also been evolving in response to the introduction of the IoT.

In the article , Avnet takes a closer look at this evolution and the technology behind it. Edge controllers are emerging that combine PLC and PC in a way we haven’t seen before.

An edge controller relies on combining real-time control with network connectivity. The key is to provide this functional combination in a way that doesn’t compromise either side. Industrial PCs and gateways represent a best-effort to achieve this but each has its own weaknesses. Can the edge controller bring balance to the IIoT?

Find the right approach

At its core, the IIoT relies on the same electromechanical, hardware and software components that enable all modern life. As a leading distributor working with a broad supplier base, Avnet also provides design services to help its industrial customers throughout their digital transformation journey.

Avnet has been doing business the right way since 1921. It has over 1,800 FAEs available to customers, support from its extensive engineering communities, subject matter expertise and access to the latest development kits. These resources will help you move from proof of concept to production faster. Avnet supports you through rapid prototyping and small volume production.

Customers have access to over a century of experience in supply chain management, to ensure your production scales. We provide assurance of supply and flexible inventory programs through a global distribution and logistics infrastructure.

Avnet’s capabilities cover technologies and solutions, design services and expertise, and supply chain and logistics. Accelerate your digital transformation to the IIoT with Avnet.