In today’s advanced industrial era, effective maintenance is paramount. Companies grapple with the repercussions of inadequate maintenance strategies, leading to unexpected downtimes with staggering costs of up to $260,000 per hour. These interruptions, frequently stemming from equipment malfunctions, underscore the pressing demand for proficient condition monitoring solutions. Enter the Industrial Internet of Things (IIoT); a game-changer that elevates condition monitoring by providing real-time insights and foresight, significantly mitigating these expensive operational halts.

What is Condition Based Monitoring?

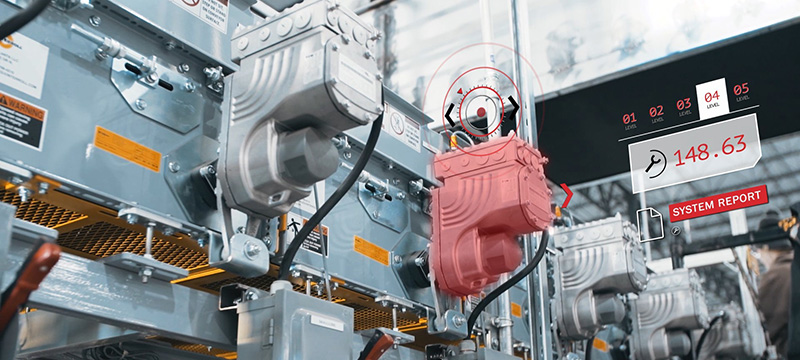

Condition Based Monitoring (CBM) is an industrial maintenance strategy that focuses on monitoring the real-time conditions of machinery to predict potential failures. This involves equipping industrial machines with sensors that collect data on variables like temperature, vibration frequency, and pressure. Once gathered, this data is sent to the cloud where it’s aggregated and analysed, providing insights about the equipment’s health and operational parameters. However, traditional CBM has its limitations, especially in terms of scalability and real-time data processing, which is where IoT-powered technology comes into play, and in particular Industrial Internet of Things (IIoT) powered technologies.

Harnessing the Power of IIoT: A Deep Dive into Industrial Interconnectivity

The Industrial Internet of Things (IIoT) is a subset of IoT that focuses on the interconnections and communications between machines. It leverages technologies like cybersecurity, big data, cloud computing, and machine learning to enhance industrial operations.

In the realm of CBM, IIoT technologies enable real-time monitoring of machinery across vast industrial landscapes. For instance, in the electric power industry, IIoT-based CBM can track the health of turbines, electrical substations, and even nuclear power plants. By integrating IIoT with CBM, businesses can overcome the traditional limitations of CBM and achieve more efficient, scalable, and real-time monitoring solutions. Harnessing IIoT technologies for condition based monitoring also brings organisations a myriad of invaluable benefits:

1. Vast Data Storage

Traditional Condition Based Monitoring (CBM) systems, which rely heavily on on-premises data centres, often grapple with constraints in their data storage capabilities. These limitations can hinder the real-time analysis and insights that industries desperately need to optimise their operations.

IIoT transcends these limitations by harnessing the power of cloud computing. This not only facilitates the storage of colossal amounts of data but also ensures its accessibility and analysis in real-time. For perspective, consider the renewable energy sector. A single wind turbine, in its operational life cycle, can generate about 1 terabyte of data every week. This data encompasses various metrics, from vibration frequencies to temperature variations, all of which are vital for assessing the turbine’s health and efficiency. The use of IoT powered technology allows this data to be accessed instantly to analyse the condition of the turbine.

2. Enhanced Analytics

The digital transformation of industries is not just about collecting data but also about analysing it in ways that were previously unimaginable. The Industrial Internet of Things (IIoT) plays a pivotal role in this transformation, especially in the realm of Condition Based Monitoring (CBM). With the computational prowess of cloud platforms, IIoT-driven CBM can deploy advanced machine learning algorithms, which not only refine diagnostic precision but also amplify predictive capabilities.

One of the primary challenges industries face is the siloed nature of data. Data is often collected infrequently, is hard to access, and is not interconnected, making it challenging to derive actionable insights. However, with IIoT, data from various sources can be integrated, offering a holistic view of operations. For instance, in the realm of manufacturing, IIoT can bridge the gap between operational technologies and IT, allowing businesses to monitor their operations remotely and in real-time. This seamless integration ensures that data from different devices, manufacturers, and systems can be linked together, providing a comprehensive picture of the operational health.

Furthermore, AWS IoT services demonstrate how businesses can integrate this technology into their operations, enhancing their maintenance strategies. By adding smart devices to equipment such as motors and pumps, businesses can collect real-time data on equipment performance. Smart devices are also used in non-destructive testing (NDT) scenarios to identify hidden cracks and rust through vibration and infrared sensors. Advanced analytics then identifies potential issues before they culminate in equipment failure, leading to significant cost savings, increased productivity, and extended equipment lifespan.

3. Data from Multiple Critical Assets

Machine learning requires significant data for accuracy. By collecting data from multiple machines across different locations, IIoT enhances the accuracy and functionality of predictive models, allowing for a holistic understanding of the condition of these assets and enabling predictive capabilities to prevent issues from escalating.

The significance of this multi-machine data aggregation is manifold. Firstly, it provides a comprehensive view of operations, ensuring that no equipment anomaly goes unnoticed. Research indicates that 64% of unplanned downtime is attributed to equipment failures, often stemming from improper maintenance or a lack of efficient machine condition tracking. By aggregating data from multiple sources, IIoT ensures a holistic understanding of equipment health, thereby reducing the chances of such failures.

Moreover, the data fetched by a condition monitoring solution offers invaluable insights about the current state of equipment and can be applied to indirectly monitor the quality of goods in production. For instance, in paper manufacturing, condition monitoring solutions help monitor the quality of paper being produced by tracking the condition of all roll presses through IoT powered technology.

Furthermore, this aggregated data serves as a rich training ground for machine learning models, enhancing their predictive capabilities. With more data points to analyse, these models can identify intricate patterns and correlations that might be missed when analysing data from a single machine. This not only improves the accuracy of predictions but also aids in the early detection of potential equipment failures, allowing businesses to transition from reactive to proactive maintenance strategies.

4. Reduced Physical Intervention

In the digital age, the ability to remotely monitor machinery through IoT has emerged as a transformative solution, especially in sectors where physical access is challenging. The oil & gas industry, for instance, often operates in remote terrains, offshore platforms, or other inaccessible areas, making routine inspections and maintenance a logistical challenge. According to a study, unplanned equipment downtime in such industries can lead to losses amounting to millions of dollars daily, emphasising the need for timely interventions1.

IoT technology addresses this challenge head-on. By equipping machinery with sensors that transmit real-time data to centralised systems, industries can monitor equipment health, performance metrics, and potential anomalies without the need for on-site personnel. This not only reduces the costs associated with sending teams to remote locations but also ensures timely interventions, as potential issues can be detected and addressed before they escalate.

In essence, the integration of IoT in condition-based monitoring is not just about technological advancement; it’s about redefining operational efficiency, ensuring safety, and driving cost-effectiveness in industries where every minute of downtime can have significant financial implications.

Conclusion

In the intricate tapestry of today’s industrial landscape, the role of IoT in enhancing Condition Based Monitoring stands out as a beacon of innovation. As we’ve journeyed through the myriad facets of this integration—from the vast data storage capabilities to the power of enhanced analytics and the promise of reduced physical intervention—it’s evident that IoT-powered CBM is not just a fleeting trend but a transformative force for industries.

However, while the allure of these benefits is undeniable, it’s crucial for businesses to approach this technology with a holistic mindset. CBM, as potent as it is with IoT, should not be an isolated strategy. Instead, it should seamlessly integrate into a broader, comprehensive maintenance plan. Such an approach ensures that businesses don’t just react to the immediate insights provided by CBM but also strategize for long-term equipment health and operational efficiency.

By weaving IoT-powered CBM into the broader fabric of their maintenance strategies, businesses stand to not only mitigate the exorbitant costs associated with unplanned downtimes but also to usher in an era of unprecedented operational excellence. As we look to the future, where AI and machine learning further amplify the capabilities of CBM, the marriage of IoT and CBM promises a horizon brimming with possibilities, setting the stage for a more efficient, productive, and innovative industrial future.