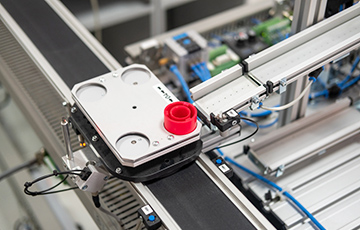

Load sensors, also called load cells or load transducers, are crucial aspects of industrial, automotive, and aerospace processes. A load sensor or transducer converts a force or load acting to an electronic signal, changing its resistance to a change output voltage in an input voltage application. Load sensors are also called strain gauges, which are the same ones present in digital weighing scales. High-quality load sensors increase quality control, from prototype to serial production.

Load sensors can be used in various IoT and IIoT applications. A typical use case is the remote control of the weight of objects in the context of smart manufacturing or smart cities applications (smart warehouses, automated inventory audit & management, remote garbage monitoring, ect). This only requires a cloud connected weighing scale to measure weights of various load capacities and wirelessly send the measured weight to a remote server for control.

In this post, you’ll learn how to check if your load sensors are of good quality or not.

Check Load Cell Capacity

Make sure that the load cell capacity is suitable for the weight of your products. If you’re looking to weigh over 20-ton containers, choose a load sensor that is capable of weighing 20 metric tons and higher. Buy a load sensor with a weight capacity exceeding the weight of items you regularly weigh.

When choosing a load cell, select one that enables operation in the middle 80 percent of the load sensor’s capacity. Ensure accurate readings by not using a sensor when measuring force below five percent of the rated capacity of the sensor. Leave a buffer on the scale’s top end to protect the load cell. It enables parts to run if they are slightly stronger than expected.

Double-check the load cell units. Make sure that the units aren’t expressed as pressure or in pounds per square inch (PSI) or Pascal (Pa) when checking them. If the units are in Pa or PSI, the sample area will be considered when a load cell is sized. Most new load cell systems read the capacity from TEDS chips, stopping when the load cell’s capacity is hit, like the products available at https://loadindicator.net/.

Know The Purpose

So, how do you intend to use a load sensor? Are you looking for a load sensor to go with a hanging scale to lift products? By knowing the objective of buying a load cell, you’ll be able to choose the right type of sensor for your needs.

Determine The Best Type Of Load Sensor

There are many types of load sensors used to measure electrical output and fulfill specific weighing requirements. The most popular load sensor types include strain gauge, single point load cells, pancake load sensors, shear beam, S type, button, compression, bending beam, double-ended, and hydraulic.

Here are the details of some types of load cells:

- Strain Gauge Load Sensor: It consists of a spring mechanism or strain gauge.

- Single Point Load Sensor: It is also called platform load cell. This allows weighing scale construction with a single load cell, which is found in small- to medium-sized platform scales.

- Pancake Load Sensor: This low-profile compression load sensor has a wide surface area that absorbs shock loads. Pancake load sensors are commonly used in heavy automotive, industrial, and material testing environments.

- Shear Beam Load Sensor: It features an oblong shape with two retaining bolts for added support, which is used in compression force testing and industrial environments.

- Button Load Sensor: It is tiny and highly recommended for minimal spaces.

- Hydraulic Load Sensor: It measures weight, and when a load is put into the load sensor, the pressure increases and can be measured by an electrical transducer.

Check The Features

Load sensors come with different features. Choose ones that are suitable for your industry. For instance, if you’re working in wet areas, you’ll need a waterproof load sensor (IP68-rated) for the best results. Now, a load sensor with advanced lightening protection is required for outdoor use.

Here are the best features of a good quality load sensor:

- Compact and durable design

- High-performance

- Accurate readings

- Appropriate weight capacity

- Lightening protection

- Waterproof

- Multipurpose measurements

- Sealed for compression and tension applications

Determine The Cost

Sensors can be expensive devices. That’s why you need to really set an appropriate budget in order to buy a high-quality load sensor with features that you really need. You have to compare the rates and the features before buying a load cell, so you’ll end up with the best and right one. By doing so, you’re not compromising accuracy and quality.

Conclusion

It’s important to check if you have a high-quality sensor. The readings should be accurate, and the load sensor itself should be able to handle items or products you need to weigh on a regular basis. The type, weight capacity, and required features are just some of the important considerations before buying a load sensor. It’s crucial to choose the right load sensor for your application or industry by following the tips shared above.